"This is our first experience with robotics and I can tell you that this is the way to go."

"This is our first experience with robotics and I can tell you that this is the way to go."

La Cántara Artisan Cheeses

Genaro and Rosselyn lease and operate a two robot dairy and milk (February 2024) roughly 63 cows 2.6 times a day on average. They currently have + 15 dry cows and approx 50 cows coming up for calving in in March/April over 28 hectares. Furthermore, the two rear roughly 100 calves on other facilities. What makes this dairy unique is the cheese factory that has been integrated within it, which allows them to converted the milk they produce into a wide range of Venezuelan styled cheeses.

Their Story

Genaro and Rosselyn met while studying for their Veterinary degree in Venezuela, South America.

“She started a year before me but at some point I took a subject in advance that she happened to be in. It was the only subject we shared throughout our studies so it was good timing!”. Genaro explained how in the long run, this veterinarian background assisted their farming by giving them a good understanding of how animals work.

“I think in some way, that background helps us understand how we can prevent sicknesses or illnesses in our cows so we try to apply our knowledge in that way to create a much more pleasant environment for our animals. We care for our cows and in some way it has a financial benefit as you’re not using as many drugs and not wasting so much milk”. Their mutual passion for animals led them to form a relationship which they’ve now been in for almost 16 years.

After finishing their studies, the two began to grow concerned about their country's political situation. Genaro recalls how there would be “riots and food shortages so we thought there must be better opportunities elsewhere”. To avoid the deteriorating political situation and pursue their passion of working with animals, Genaro and Rosselyn acquired working visas in 2011 and moved to Queensland. The two began learning English and found their first job on a small beef cattle farm in Texas. In their 18 months of working this job, Genaro and Rosselyn began their journey towards dairy farming.

“In that first beef job I learnt how to ride a motorbike, I learnt how to fix a water pipe, how to fix fences, drive machinery and all those sorts of things. They’re crucial because in the future you are going to be telling people to do those things so it's important that you know yourself how to do them. We got all those really basic skills at the beef farm.”

In early 2012, Genaro and Rosselyn moved to New South Wales and began working as farm hands on a 950 cow rotary dairy. Genaro's work involved getting the cows in, taking them back to the paddock and assisting in setting up fences while Rosselyn was responsible for fitting calves. Over the course of two years they became more proficient in their jobs and gained additional responsibilities such as treating sick cows, doing milkings and even managing other employees.

“In this job we started learning about rotations and a little bit of pasture management. We learnt about irrigation and obviously we put into practice a lot of animal reproduction as we were doing ai’s and preg testing.

Having now worked on a dairy farm and being familiar with its processes, Genaro and Rosselyn moved to south west Victoria as a herd managing couple. Although they were only in this position for 6 months, Genaro recalls how it taught them things about people management and showed them a different way of farming.

“Because we were coming from NSW where it was mainly an irrigated system, going into a high rainfall area is a completely different scenario and you’re dealing with different types of terrain. Being exposed like that to a whole different situation provides you with different skills”.

With their new learnings, Genaro and Rosselyn went back to NSW. They worked on the farm they were previously employed but this time with a higher position and afterwards worked on another dairy in Hunter Valley as a 2ic couple. From these positions, they managed a larger team with increased responsibilities, which exposed them to bigger challenges.

Genaro and Rosselyn later received their first jobs as a farm manager couple in Tasmania to manage a 950 cow dairy in an area called Roger River.

“It was our first time having the responsibility of the whole show, cause as a 2ic or a herd manager you still have someone above you and someone making those big decisions but now the responsibility was all ours. Obviously the owners were around, they didn’t live on farm but they were visiting the farm weekly, however the day to day decisions and how you do things were all up to us.”

Genaro further described the challenges that himself and Rosselyn had to face while managing this farm over two years.

“It was a very wet farm, probably one of the wettest farms around the district. The way we looked at it, after you work at one of the most challenging farms around the area, anything after that is a lot easier. It was still a productive and beautiful farm but in terms of management it was difficult because the farm had one of the biggest rivers in Tasmania surrounding it. It provided many challenges for this reason but was still a great experience. It gave us the opportunity to manage a farm on our own and gave us great exposure to Tassie’s dairy industry. Coming from NSW where dairies are generally ran as a high input system, into Tassie where most farms are low input systems, most of the feed will come from the grass and grain with supplementing being minimal compared to what you would do in NSW. We learnt how to adapt.”

The two moved once again and began share farming on a 500 cow dairy in Edith Creek for another 2 years. During their time working there, the dairy saw the most amount of solids produced and milked the largest amount of cows than it had ever done. With their success and constant improvement, Genaro and Rosselyn found themselves moving towards the goal of a 50-50 share farming arrangement and eventually being able to purchase their own dairy farm. However, after recognising that this would not be an option on the dairy farm they were currently working on, they began brainstorming some ideas.

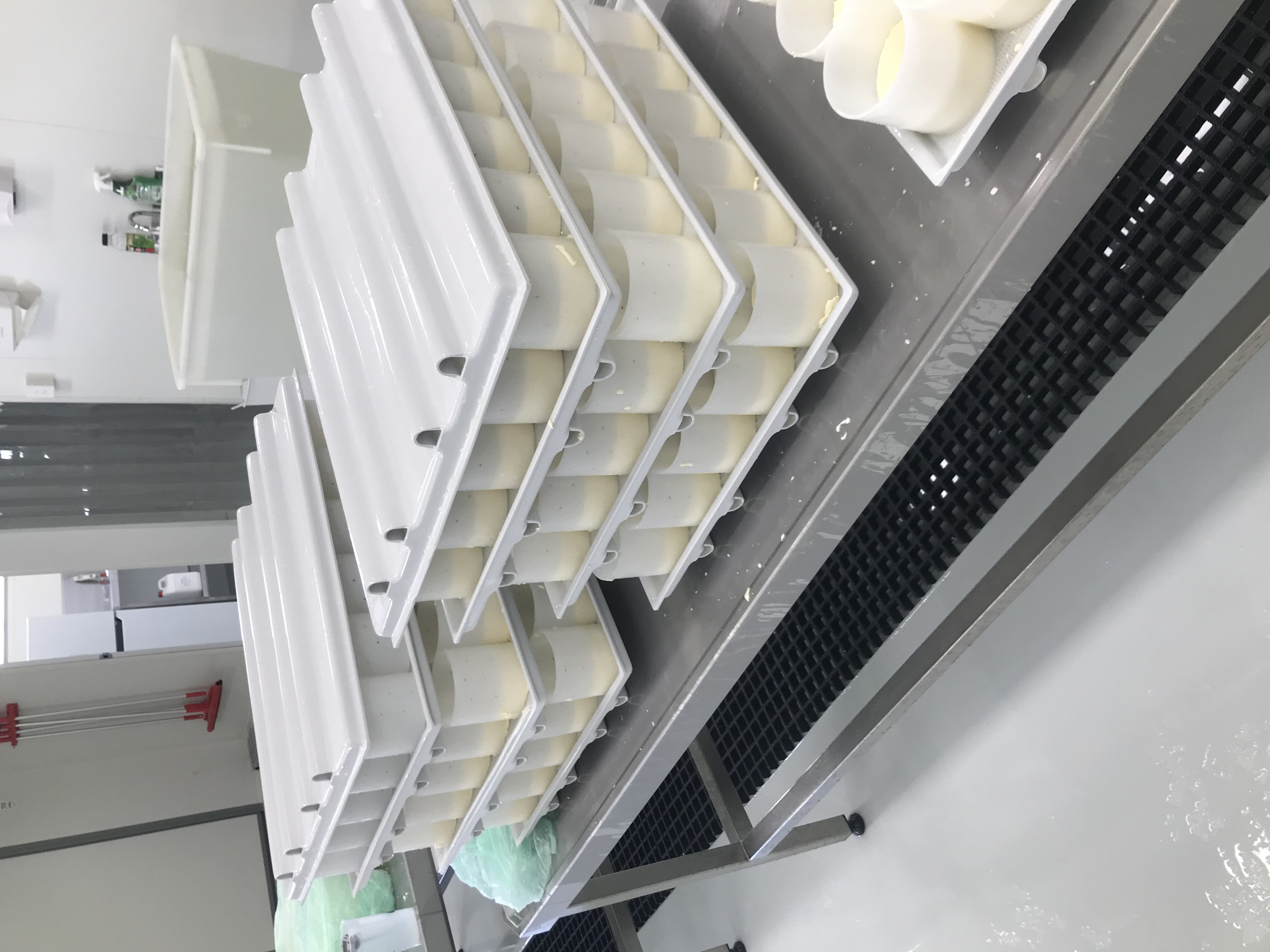

So How is The Cheese Made?

Milk gets harvested by the robots and from there it is pumped into a pasteurizer. The milk is then transferred over to a cheese vat where calcium chloride is added. During the pasturisation process, calcium is lost so it must be added back in as it acts as a glue to keep molecules and proteins together. Afterwards bacteria, yeast or mould are added depending on the type of cheese that’s being made. A rennet is used to separate the milk into curds and it is then stirred. The amount of time spent stirring is again dependent on the cheese being made. The curd is heated up by adding hot water until a certain temperature is met. Once it has the right consistency and acidity, they are drained by separating and extracting all the weigh out of the curd. Next the curt is transferred into different molds and it undergoes a draining process before being left in brine. After leaving the brine they are drained once again and taken out of the moulds.

Their Experience with Lely Robotics

“I think if it was a conventional dairy it would’ve been a nightmare. This is our first experience with robotics and I can tell you that this is the way to go. I tell this to everyone, in our experience there’s no way we would go back to a conventional system. If we’re ever in a position to buy our own farm or have intentions of setting up a brand new dairy, there is no discussion to be had, this is the way to go.”

“I think it provides the best conditions for both the animals and the operators in terms of flexibility. If it wasn’t a robotic dairy there is no way we could have managed to do cheese and dairy farming altogether. Our focus was to make cheese and in a conventional dairy it would have taken that focus away from us cause we would’ve had to spend 3-4 hours in a dairy every day and that’s time we needed to work in the factory. The flexibility that it gives you as a producer is just priceless.”

“We’ve heard some people say how do you go about alarms going off in the middle of the night and I think it’s all about balance. The fact is that we’re not spending two, three, four hours in the dairy every single day so quite honestly I don’t care if it calls me at one in the morning every now and then. In two years I think we’ve probably had two or three calls in the middle of the night and they have all been a ten or fifteen minute fix. These two or three times we’ve been called out have just been simple things and yes you’ve been called at one or two o'clock in the morning but otherwise you would have to be up at three or four o’clock every single day to go and get cows in and then you have to spend two or three hours milking and that's in a small dairy scenario, a big dairy can be four or five hours and then that’s twice a day, then you have to go and chase cows in the middle of the night and when you take that all into consideration, I believe this is certainly the way to go.”

“In the two years we’ve been milking here we haven’t had not one lame cow. We’ve had just five mastitis cows and our cell count sits below one hundred thousand all year ‘round. We try to prevent things from happening ourselves but a lot of these have got to do with how the system works. The fact that cows are not all coming in together at the same time and not all hanging in a big mob, it make it a very low stress system and you see that reflected in the quality of the milk and health of the animals. These are things that help you close that initial price gap quicker. Yes it may be a bit more expensive initially but the time you take into consideration you’re not treating as many cows with mastitis, you’re not spending money on drugs, dumping milk, that’s all money that you’re saving.”

Future

When asked what they enjoy most about farming, Genaro responded saying it was a combination of different factors.

“The lifestyle is part of it. We enjoy the country life but also being able to produce the best quality food possible. The other side we enjoy is producing good quality animals and being able to look after them, treat them and spoil them when we can. We can already see the difference between what we initially got and where we’re at now and how the quality of our animals and conditions are improving so I think it’s a combination of the lifestyle and the fulfilment of producing good quality food and looking after our animals”.

In the future, Genaro and Rosselyn hope they can use their farming knowledge they’ve gained from Australia to educate Venezuelan farmers.

“We could go over to share our knowledge with farmers there and help them develop the industry a lot better, it doesnt necessarily need to be in the way of creating a business but instead a payback or a contribution to the country. To try and share all of the knowledge we’ve gained over the years.”

Our customers